Haptron Scientific

Company Mission: Empowering the Industry with Effort and Creating Value with Effort

Company Profile

Haptron Scientific (Shenzhen) Co., Ltd. was established in 2019. It is an optical force sensor company that integrates R & D and production to "endow high-level force sensing technology. Haptron Scientific independently developed the Photon series of multi-dimensional force sensors, which can be used in collaborative robots, precision processing, aerospace, medical equipment, new energy vehicles and other fields, providing customers in all walks of life with one-stop force sensing demand solutions.

Haptron Scientific Established

Product landing application scenario

R & D team

About us

Haptron Scientific Products

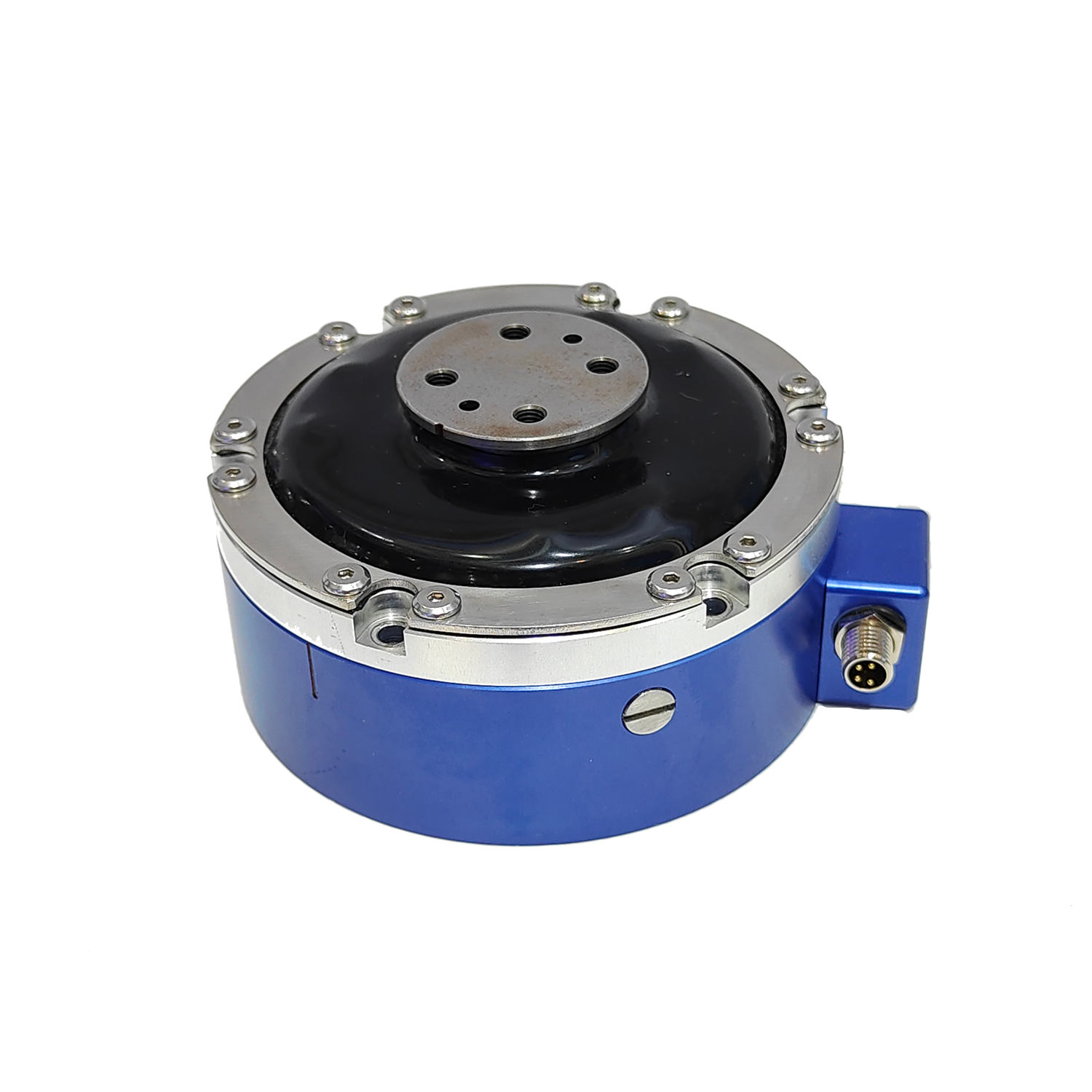

Force and torque sensor

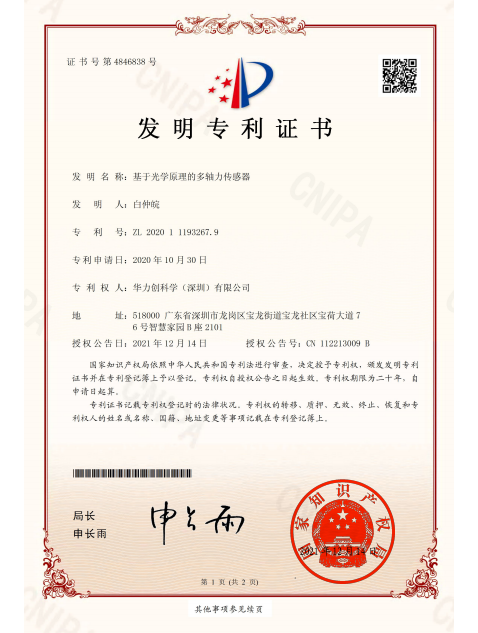

Haptron Scientific force/torque sensing technology is the first successful force and torque sensing technology based on optical principles in the world. For the first time, the technique realizes the application of non-laser light source to measure the deformation of micron-level materials, and realizes the accurate measurement of force and torque. The sensing principle incorporates a special sensing structure developed for the purpose, which reduces the overall structural limitations while ensuring the physical parameters, and uses a special optical chip to ensure the stability of the sensing unit and reduce the system error.

Intelligent end effector

Haptron Scientific Intelligent End Actuator integrates various types of actuators on the basis of mature multi-dimensional force perception, combining "force perception" with "efficient execution" from the bottom, and meeting the "perception execution" requirements in sensor applications in one stop.

Solution

Haptron Scientific independently developed the Photon series of multi-dimensional force sensors, which can be used in collaborative robots, precision processing, aerospace, medical equipment, new energy vehicles and other fields, providing customers in all walks of life with one-stop force sensing demand solutions Program.

Collaboration/Industrial Robots

By implanting joint torque sensors on the collaborative robot, the robot is endowed with more flexible force control ability. With the end Photon series six-axis force sensors, the collaborative robot has fine force control closer to the human arm. The end of the collaborative robot can also be equipped with Photon_AC intelligent collision avoidance unit to obtain the safety protection of collision and stop.

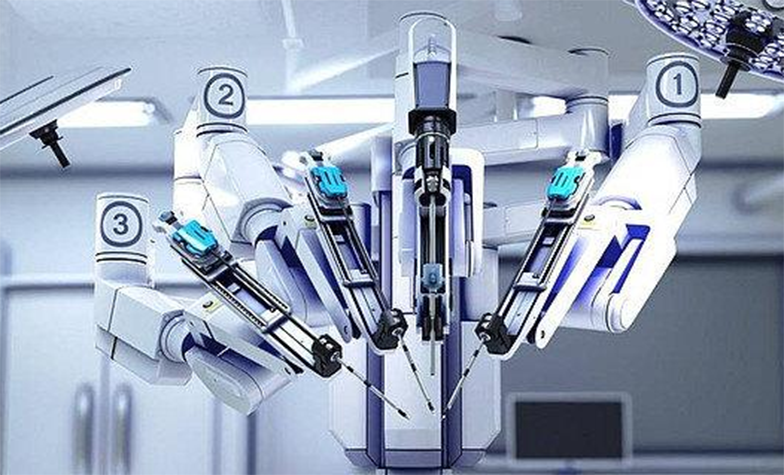

Intelligent Medical Devices

Photon_Micro is known to be the world's smallest medical force sensor. The sensor diameter is only 6-8mm, can be integrated in all kinds of endoscopic systems and laparoscopic surgical instruments, with visual display system, can assist doctors in the process of diagnosis and treatment, monitoring the contact state between the instrument and the human body cavity, effectively improve the safety of endoscopic surgery and flexible endoscopic examination and surgery.

Application Case

Our technology has been applied in many industries.

Humanoid mechanical arm

The PhotonR56 sensor is a six-dimensional force sensor developed for ultra-light humanoid manipulator. The sensor has built-in high-precision embedded signal processing circuit, moderate size and weight, reliable and durable, can seamlessly adapt to the ultra-light humanoid manipulator commonly used in the market, and can be widely used in new retail, new catering, life services, commercial services, smart home and other application scenarios.

Collaboration/Industrial Robots

The PhotonR80 sensor series is a six-dimensional force sensor developed for collaborative robots with a load of 3~20kg. The series of sensors can be adapted to the vast majority of collaborative robots and some small industrial robots on the market. The series of sensors are easy to install, stable and reliable, and can meet the human sense sensing needs of collaborative robots in one stop.

Power-assisted bicycle

The Photon_Bike sensor is a dynamic torque sensor developed for the field of power-assisted bicycles. It can be quickly customized according to the needs of different models and the structure of the five-way tube. It can record the pedaling torque and cadence at the same time. The product has high accuracy and no output in a static state., Can fully meet the requirements of cyclists for power-assisted pedaling.

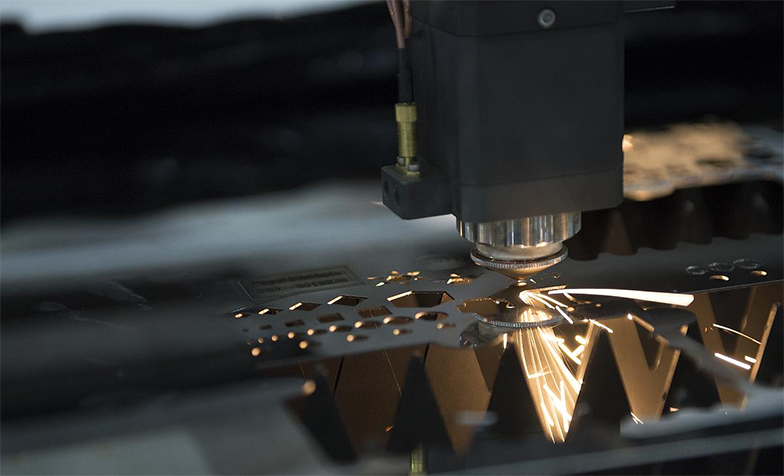

Precision machining

PhotonOne series sensors are high-stiffness three-dimensional/six-dimensional force sensors developed for precision machining. The shape and structure of the sensors are highly customizable, with high stiffness and stable signal transmission, which can monitor the precision machining process. At this stage, the products in this series have been applied to five-axis CNC machine tools, multi-axis polishing machines and other equipment, which can effectively improve the yield of various types of precision machining and reduce the risk of equipment failure.

Intelligent Medical Devices

The Photon_micro series medical force sensor is a miniature six-dimensional force sensor developed for medical scenarios and is known to be the smallest medical force sensor in the world. The sensor has a diameter of only 6-8mm and can be integrated into various endoscopic systems and laparoscopic surgical instruments. With a visual display system, it can assist doctors in the process of diagnosis and treatment and monitor the contact state between the instrument and the human body cavity.

New energy vehicle

Photon_AO vehicle torque sensor is a vehicle torque sensor developed for the automotive field, especially in the field of new energy electric vehicles. The sensor can sense the real-time torque on each half shaft (and traditional shaft) in real time, and the vehicle does not need to change the original drive shaft structure. The sensor has high accuracy and high reliability, and can be used in vehicle testing and multi-motor electric vehicle electric drive control In.

Precision Equipment Protection

Photon_AC series intelligent anti-collision unit is an intelligent unit integrating "real-time sensing and automatic avoidance" developed by Haptron Scientific. It can be installed between precision equipment and moving mechanism to protect high-value precision equipment such as laser head and scraper. The sensor can sense the contact force received at the end of the precision equipment, and the user can customize the avoidance trigger force according to the requirements. Before reaching the trigger force threshold, the overall stiffness is high, the stability is good, and the jitter for the movement process is avoided. After reaching the trigger force threshold, the avoidance trigger response speed is fast, and the stiffness can be rapidly reduced within 2ms, thus protecting the safety of the equipment. The product has been applied in the field of laser application, with high reliability and good effect.

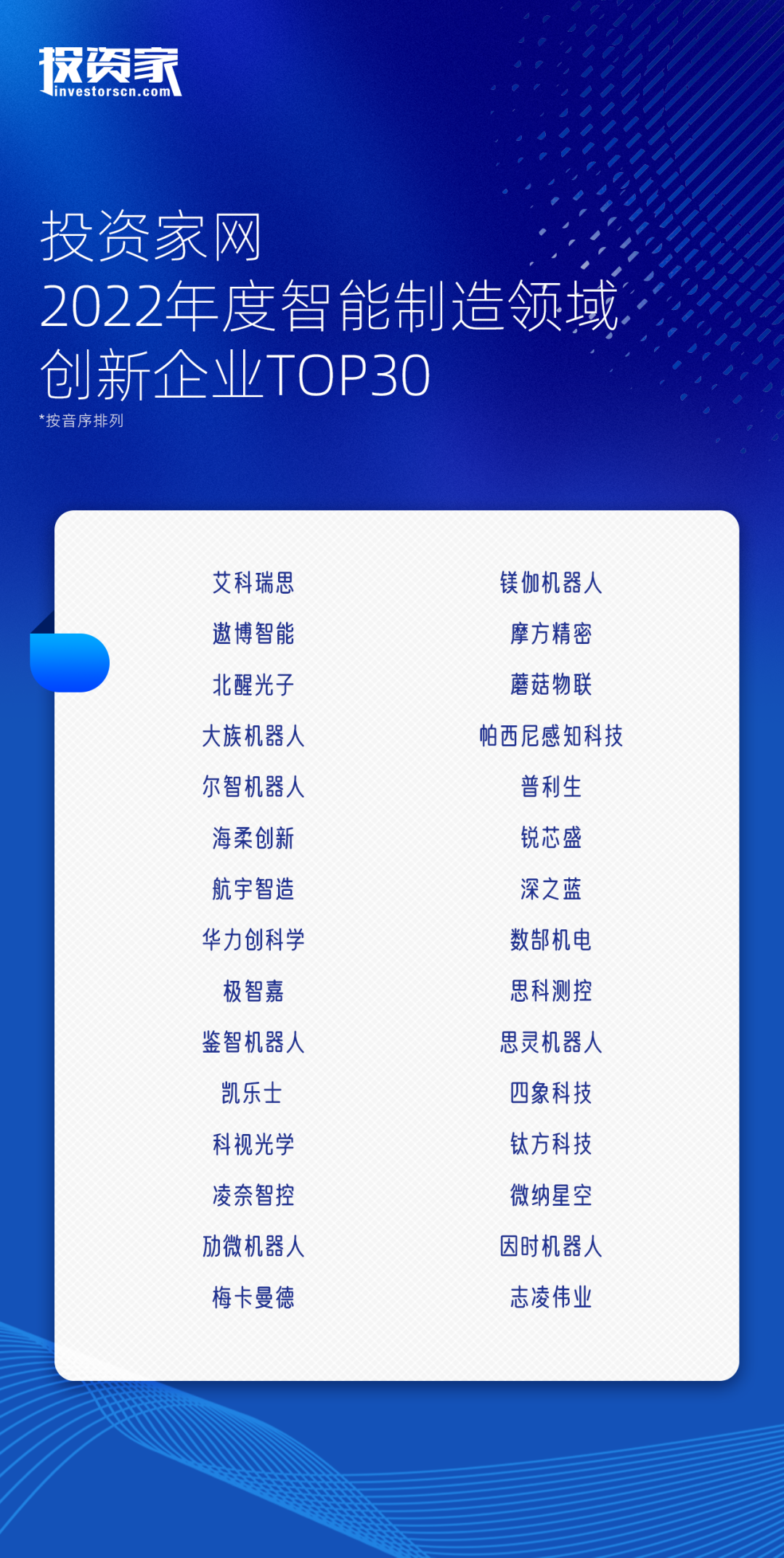

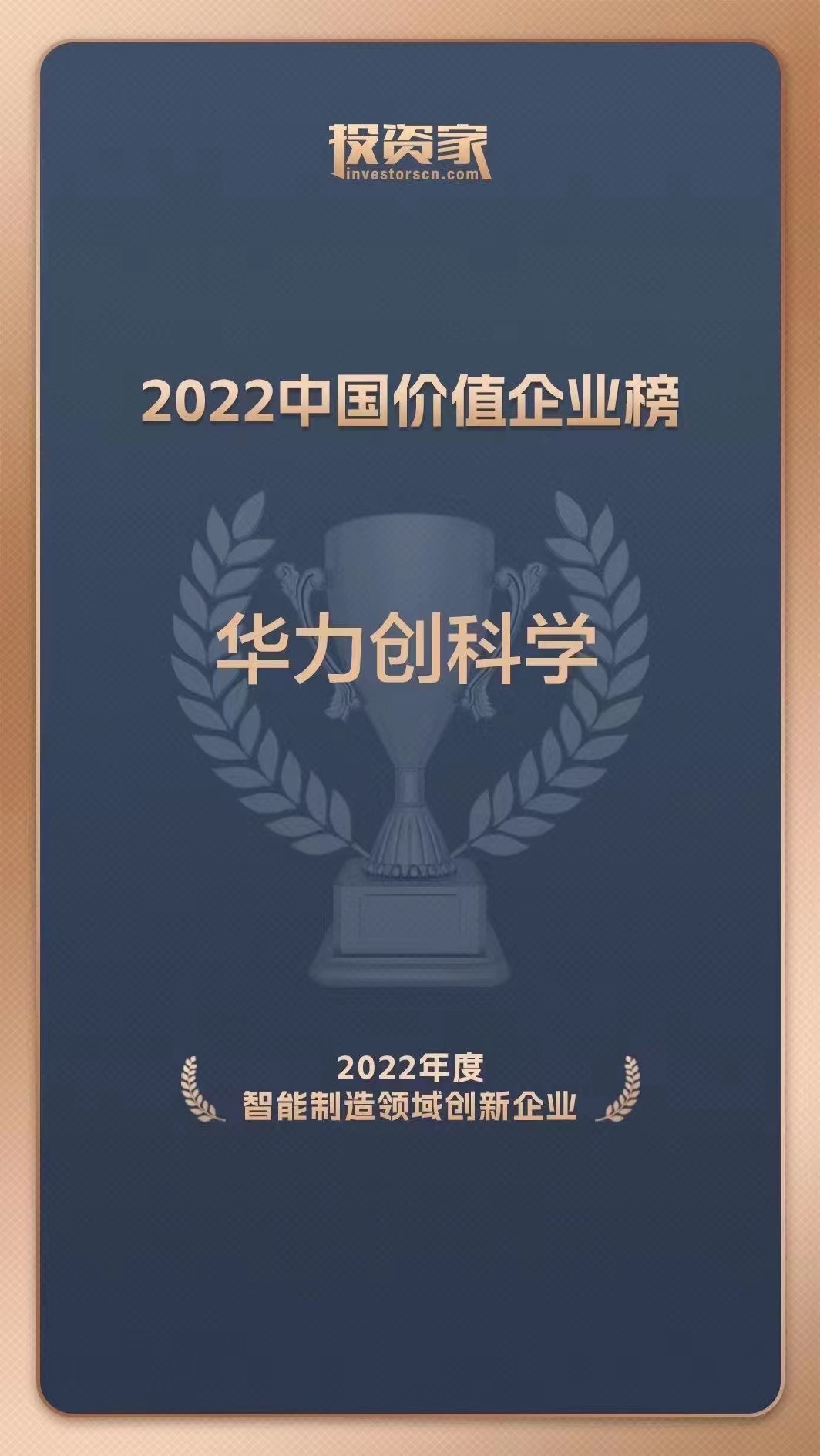

Qualifications and honors

Our products have been awarded a number of invention patent certificates, with good market reputation and user reputation.

Our Cooperative Clients

ALL

Cooperation Customers

Cooperative Hospital

Cooperative scientific research institutions

News

2023-11-25

2023-11-17

2023-11-11