Haptron Scientific has been re-invested, and the first fully automatic optical force sensor production line will be put into operation soon.

Release time:

2023-07-22 12:42

Source:

Source

Founded in 2019, Haptron Scientific is a technology innovation company with the mission of "giving high-level force perception technology. The aim is to provide high-performance intellectual ability sensors based on optical principles for various industries. At the same time, it can also integrate "visual-touch" fusion robots with robots, vision systems and intelligent control algorithms to develop overall force control solutions for target customers and solve the pain point problem of "lack of force perception" in various industries.

The lack of force sensing ability is the key problem that restricts the realization of high-level intelligence in various industries, and force sensing technology and force control technology are the key keys to solve this key problem. At this stage, in the fields of precision machining, aerospace, surgical robots, 3C consumer electronics production, military product processing, etc., traditional force sensor technology cannot meet its complex process requirements, and therefore cannot be fully applied in the above-mentioned scenarios. With its unique optical-based force sensing technology, Haptron Scientific has created a perfect solution for all kinds of complex needs.

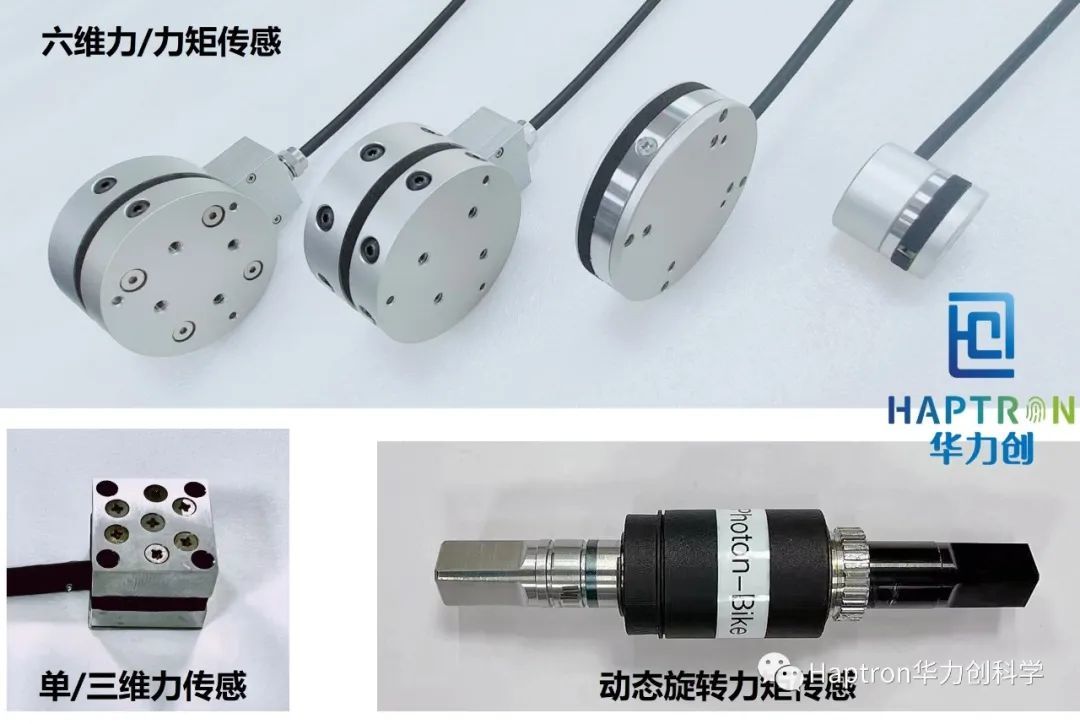

"February Spring Farming Changxing Dense, Hundred Flowers Strive for First"-Force Control Products Blooming More

Based on mature optical principles, Haptron Scientific has introduced a variety of high-precision force sensors/sensing modules. The products include: Photon series universal six-dimensional force/torque sensors, which can meet the sensing requirements in the fields of detection, testing, scientific research, etc. PhotonR a series of six-dimensional force sensing modules, which integrate the communication module into the sensor and are compatible with various types of cooperative robots. PhotonS series of customized sensors, the number of sensing shafts can be increased or decreased or the overall rigidity can be increased according to customer requirements. Photon_DY dynamic torque sensor can be used to measure the dynamic torque on the rotating shaft; Photon_AO series of vehicle torque sensors can be used to monitor the torque output on the transmission shaft of new energy electric vehicles. Photon_micro series micro multi-dimensional force sensor, known as the world's first 8mm-level six-dimensional force sensor, can be integrated into medical devices with extremely high space requirements.

Figure: Haptron Scientific Photon Series Force Sensors

Dr. Yu Chen, head of the company's products, said: "Compared with static force sensors based on strain gauges, Photon series multi-dimensional force/torque sensors have high cost performance, good decoupling capability and small crosstalk between different shafts. At the same time, the manufacturing cycle is short, the product consistency is high, there is no quality difference between batches, and it can easily cope with the application scenario of" small batch, multi-variety. Compared with dynamic sensors based on "inverse magnetic deformation", Photon series dynamic rotational torque sensors have stable output at low speeds and do not require modification of the drive shaft structure, so they can be used in multi-motor new energy electric vehicles and power-assisted bicycles. The field is applied.

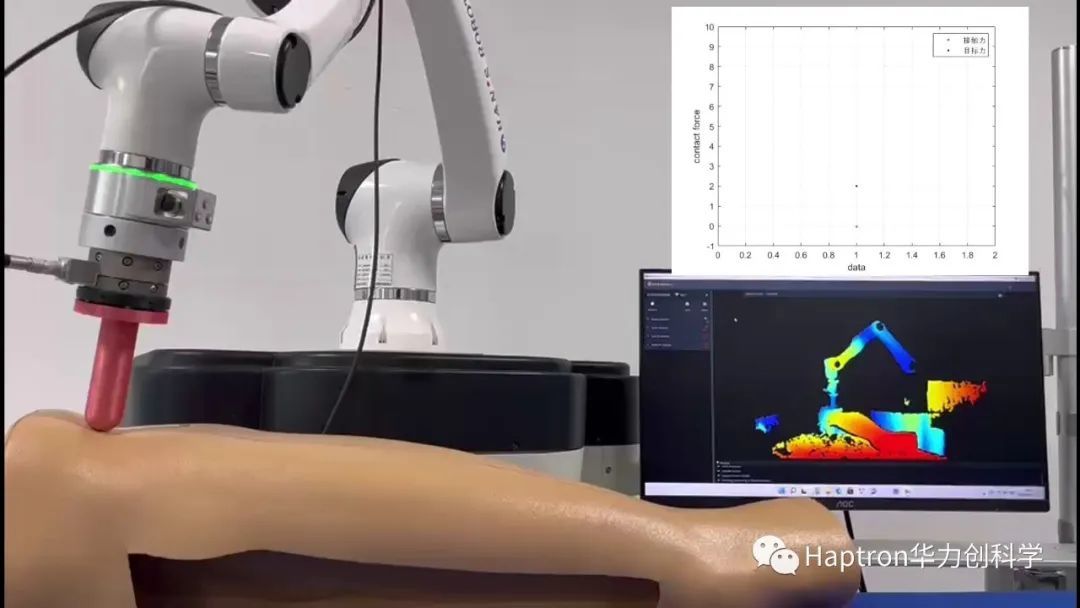

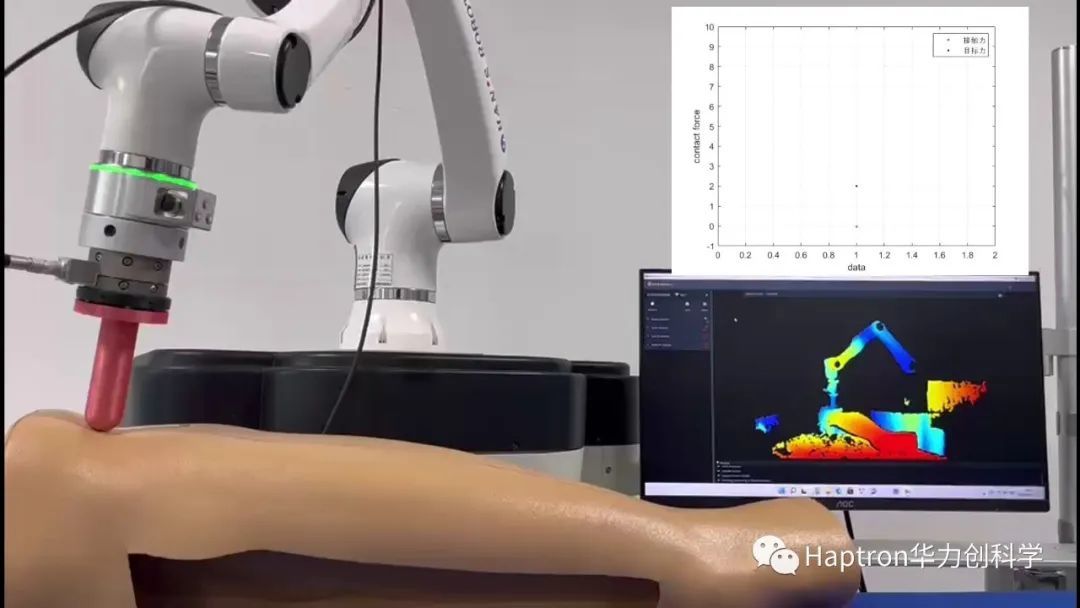

Haptron Scientific can provide not only the sensor itself, but also the robot force control algorithm developed for the application, but also the overall force control solution provided for the target scene. In addition to the core technology of Photon sensor, Haptron Scientific has created a visual-tactile fusion intelligent robot platform based on Photon sensor. At this stage, the force control exploration algorithm for high-order and flexible surfaces has been developed and verified, the robot feedback control algorithm under 2D and 3D vision has been developed, and the "visual-tactile fusion" intelligent controller adapted to medical robots is being developed. In the foreseeable future, the platform technology will better meet the needs of the medical, precision processing, industrial and consumer electronics industries.

Figure: Schematic Diagram of Photon Hap Force Control Algorithm of Haptron Scientific

"Ask where the canal can be so clear, only the source of running water"-a proven core technology

Haptron Scientific and technology genes from King's College London. Dr. Junghwan Back and Dr. Yu Chen, chief technology officers of the company, have been developing force sensing technology in the robot tactile laboratory of King's College. The laboratory was founded by Professor Liu Hongbin, the current researcher of the Institute of Automation of the Chinese Academy of Sciences, the executive deputy director of the Artificial Intelligence and Robotics Innovation Center of the Hong Kong Institute of Innovation of the Chinese Academy of Sciences, and the doctoral director of King's College London. It is dedicated to the development of flexible minimally invasive medical devices with tactile perception. And an international laboratory for robotic systems. Since its establishment in 2012, the laboratory has relied on the world-renowned School of Biomedical Engineering at King's College London, and has always maintained an international leader in the field of tactile perception and intelligent medical robots.

Figure: Queen Elizabeth II visits the Robot Tactile Laboratory at King's College London. The narrator is Professor Liu Hongbin.

The technological advantages of Haptron Scientific are derived from the first successful force sensing technology based on optical principles in the world. For the first time, the technique realizes the application of non-laser light source to measure the deformation of micron-level materials, and realizes the accurate measurement of force and torque. The sensing principle incorporates a special sensing structure developed for the purpose, which reduces the overall structural limitations while ensuring the physical parameters, and uses a special optical chip to ensure the stability of the sensing unit and reduce the system error. The sensing structure using this principle can be extremely small and thin in theory, which can break the limits of the existing technology in precision and structure size, and can also break the technical gap between dynamic and static force sensors.

Figure: Multi-dimensional Force Sensor for Haptron Scientific Photon micro Endoscope

"The horse-made Lu is fast, and the bow is like a thunderbolt."-the market points to a steady, accurate and fast market.

On the market side, Haptron Scientific focuses on precision processing and manufacturing, and strategically lays out major competitions such as medical devices and new energy electric vehicles. With the core value of "force sensor solution", the head enterprises of the above-mentioned large scene are customized and empowered.

In the field of precision machining, Haptron Scientific aims to upgrade all kinds of equipment to meet the needs of users for monitoring the production process, reduce the risk of failure and improve product yield. At this stage, customized force sensing scheme has been provided for the head listed enterprises in the field of metal 3D printing. At this stage, the products have been finalized for mass production. Haptron Scientific has also obtained the bar code from a supplier of a research institute in the aviation industry. The targeted development of high-precision force control grinding equipment has reached the accuracy of 2um and will be delivered in batches before the end of the year. In addition, it has also provided a polishing device force control solution for an Apple product automation equipment manufacturer, and has now completed multiple rounds of testing.

In the field of medical devices, Haptron Scientific aims to endow intelligent medical devices with high performance perception ability, and provide new solutions to the problems that cannot be solved in clinical treatment at present, so as to benefit patients and doctors. At this stage, we have reached a cooperation intention with a number of enterprises to endow medical devices with tactile perception.

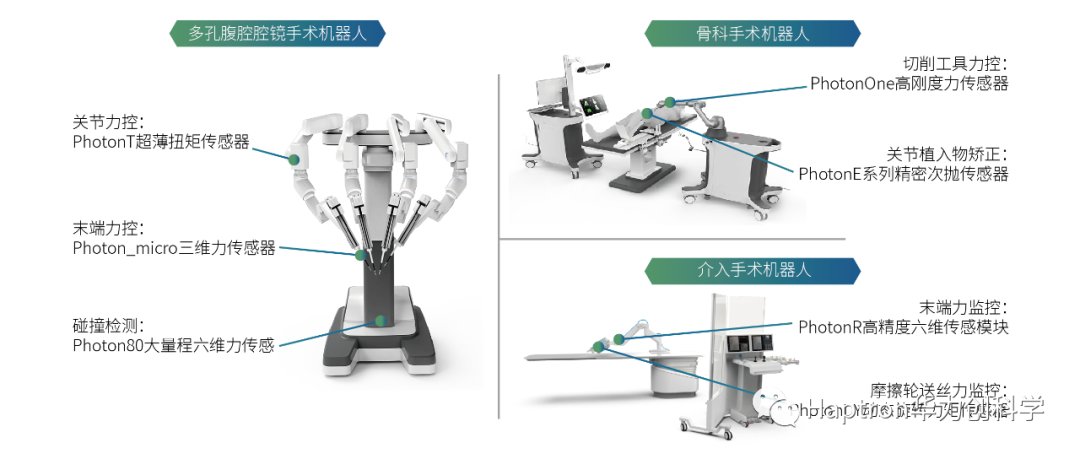

Application Scenarios of Haptron Scientific Photon Series Force Sensors in Medical Devices

In the field of new energy electric vehicles, Haptron Scientific aims to give vehicles a new method of wheel-end state perception, so as to improve the vehicle condition perception ability and simplify the difficulty of vehicle control. At this stage, the dynamic torque sensor products have been sent to a certain head electric vehicle enterprise, which can be finalized and mass produced after the test is correct.

Investor views:

The six-dimensional force sensor is in the card neck link in China, the traditional domestic existing products based on the principle of strain gauge still have a gap with foreign countries, and the traditional principle also has the shortcomings of not miniaturization, low yield, poor consistency and so on. Haptron Scientific team has successfully developed the world's first force sensor with new optical principles. Combined with visual-touch fusion solutions, it has led the development of force sensing technology, better solved the pain points of traditional principles, greatly broadened the force transmission sensing scenarios, and enabled the leapfrog development of high-end manufacturing, medical equipment, aerospace and military industries with "force.

Hongchuan source fund has been in the hard technology track depth layout, continue to be optimistic about Haptron Scientific company in the era of intelligent sensing explosive power and prospects, believe that the first fully automatic optical force sensor production line will accelerate the industrialization process, help Haptron Scientific company to become the invisible champion of the force sensing industry!

(The article is reprinted from the investor network)

More news recommend